A SMOOTH

SUCCESS

HATAG Fouling release film

Innovative, eco-friendly and cost-effective

Latest news

DNV

According to the recently published „Maritime Forecast to 2050” by DNV, global shipping is finding itself in a “decisive decade” to drastically reduce its CO2 emissions. A DNV press release states: "The shipping industry is facing increasing regulatory pressure with regard to decarbonisation. Most recently, the World Shipping Organization (IMO) tightened its requirements in July. According to this, the industry is to reduce its greenhouse gas emissions by 20% by 2030 and to net zero by around 2050. To meet its expected annual fuel demand of 17 million tonnes of oil equivalent (Mtoe) by 2030, shipping needs 30-40% of the world's projected CO2-neutral fuel supply. Ship owners should therefore broaden their view beyond the issue of fuels and examine what measures they can take today, especially to increase energy efficiency and reduce CO2." The HATAG FRS system is an important component in the complex response to this challenge. The system with the FRF Fouling Release Foil on an epoxy-based corrosive protection barrier ensures the continuous maintenance of smooth, friction-free underwater surfaces. This leads to significant savings in fuel costs and corresponding reductions in emissions: Tests have already measured a reduction in drag of eight to 14 per cent. The silicone-based, multi-layered film for protection against biofouling in the underwater area provides non-toxic fouling protection. Already at a hull speed of five to six knots, the fouling is removed from the hulls and falls back into the natural environment. Neither toxins nor microplastic particles, as with conventional antifouling paints, are released into the water. The FRS system is an ideal solution for the protection of all surfaces in the underwater area, both from an ecological and an economic point of view. Pilot projects and initial practical experience have confirmed this and delivered very positive results. DNV Maritime CEO Knut Ørbeck-Nilssen stressed on the occasion of the report mentioned at the beginning that it is not enough to focus only on alternative fuels: "Ensuring a greener fuel supply is essential. However, focusing on fuels alone may prevent us from making a difference already in this decade, and ambitious declarations for the future alone are not enough. We need sustainable steps to reduce emissions," the DNV press release states. The HATAG FRF film is just such a step.

Premiere at the “Interboot“ Boat Show

A special exhibit at the boat show “Interboot” on Lake Constance demonstrated once again how versatile the HATAG FRF film is. After a successfully completed and now continued pilot project on a gas tanker, on authority vessels, ferries and yachts, a fast inflatable boat was now, for the first time, protected with the film after successful tests in May 2023. The Highfield brand RIB is used as a racing boat and is in the water all year round. The multi-layer Hatag FRF silicone-based biofouling protection film provides non-toxic fouling protection. Neither toxins nor microplastic particles are released into the water, as is the case with conventional antifouling paints. The HATAG FRF film is particularly relevant in these specially protected inland waters. The HATAG FRF film on the underwater body of the RIB was applied by the company “Bodensee-Bootsfolierungen”, and the boat was exhibited at the fair. More information: Bodensee-Bootsfolierungen.de

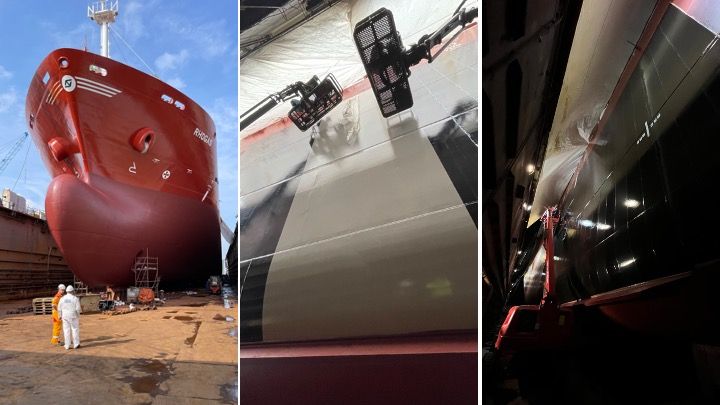

Practical Test of the FRS Fouling Release System – Positive Results.

In the summer, part of the underwater hull of the gas tanker "Rhogas" was protected with the Fouling Release System FRS from HATAG maritime and GTF Freese. An interim assessment was so positive that the shipping company now wants to continue the pilot test on a larger scale. A pilot test with the FRS system on a Sloman Neptun gas tanker was successful, as SL Managing Director Guido Försterling and Vessel Performance Manager Jost Lüdke report in the magazine "Hansa". Now the trial is to be extended to other ships and to be able to assess the film over a whole year. Some of the most important questions have already been answered during this pilot test. Sloman Neptun Managing Director Guido Försterling, for example, said in the "Hansa" interview: "The film adheres - we can say that after half a year - unreservedly well." And Vessel Performance Manager Jost Lüdke added (in the same interview): "We have not even observed any mechanical damage so far." This refers to possible damage caused by the vessel lying on fenders or during locking. Filming with the FRS system has also proven itself in "everyday ship life", they said in the interview. Guido Försterling explained: "With this film, on the one hand you have to clean the ship less often under water and on the other hand damage can be repaired both above and under water with on-board means." This is of course an important point in view of the fact that it is not allowed to paint outboard with conventional paints. Regarding the costs, Försterling said, "We assume that the system is significantly cheaper than conservative antifouling products in the lifecycle consideration due to its durability and hydrodynamic properties." The properties mentioned also include the expected savings in fuel costs (by up to ten per cent) as well as the associated, correspondingly greatly reduced emissions. The application of the system, consisting of an epoxy-based, solvent-free primer and the actual film, worked very well at the Bredo shipyard in Germany, the interview continued. However, this cannot simply be transferred to "any shipyard" anywhere in the world. HATAG maritime has been working for some time to train a network of certified applicators who can then apply the film in the shipyards. But what is Sloman Neptun's conclusion after this first test run? Guido Försterling once again: "We would like to foil more ships next year, when we will have to do some dockings. Also, as reported at the beginning, to test the FRS system under real conditions over all 12 months of a year and the corresponding climatic conditions. Download PDF

Strict rules to ban biofouling on ships in New Zealand and Australia

It seems that invasive barnacles transported by shipping and unwanted marine biofouling could be an increasing problem in Australia, New Zealand and possibly also other parts of the southern oceans. The New Zealand government website of the Ministry for Primary Industries (mpi.govt.nz) says on biofouling: “Marine pests and diseases introduced to New Zealand on vessel hulls (biofouling) are a threat to our marine environment and resources. All vessels arriving in New Zealand must provide evidence of biofouling management prior to arrival.” The stance taken in Australia is quite similar, where strict rules on banning biofouling have been in effect since June 2022. These demand that that ship operators should “demonstrate implementation of proactive management practices” with regard to fouling and that authorities may inspect hulls and “manage” unacceptable fouling. These rules are strictly implemented, as shown in December 2022 and January 2023, when two cruise ships – the Viking Orion and the Coral Princess - were denied entry into New Zealand and Australian ports and coastal waters. For the Viking Orion, the problem of biofouling was established while in Wellington port. The ship was consequently banned from stopping at Christchurch and Dunedin, also from visiting Hobart on Tasmania. Before finally entering Adelaide port, the ship had to be cleared of underwater biofouling by divers sent by the Australian authorities: “The vessel is required to undergo hull cleaning to remove the biofouling and prevent potentially harmful marine organisms being transported by the vessel,” the Australian Fisheries Management Authority said in a brief statement. In case of the Coral Princess, a cruise through Milford Sound and a stop at Port Chalmers had to be cancelled after snails were found on her hull. Maybe on a lesser scale, but equally noteworthy, is the problem being encountered by participants of the “Golden Globe Race”, sailing in the Southern Ocean and who are being slowed dramatically by excessive barnacle growth on their yachts. Again, traditional antifouling paints quite obviously cannot cope. #foulingreleasesystem #hatagmaritime #foulingreleasefilm #antifouling #biocidefree #hatagfrf #hatagfrs #freese #tefrocor150

HATAG maritime now also represented in New Zealand

He has been involved in seven America’s Cup campaigns and also has a wealth of offshore racing experience. Yachtsman Steve Wilson from New Zealand has not only been active in the international Grand Prix and Super yacht racing scene, but also in the global yachting industry. As one of the founders, in 1987, of “Southern Spars” who were among the first to professionally make carbon-fiber masts, spars and other parts, he and his fellow-founders sold the company in 2000 but he stayed on in a senior roles until 2005. Since then, Steve has been active as an independent consultant mainly inAmerica’s Cup projects and more recently in the independent design and project management of various yacht riggingprojects. During a complete refit of his own 55-foot, Greg Elliott-designed performance cruising sailing yacht in 2021/22, he also had a very close look at the question of how best to protect his yacht’s underwater hull from unwanted marine growth attaching itself to it. “In this part of New Zealand”, he explains, “we have a very serious problem with very aggressive barnacle growth on boats and all other underwater structures. Up to the point where the usual antifouling paints are not very effective anymore.” With to the growing awareness for marine conservation, highly toxic paints are being phased out and other paint solutions are not as effective. Being the marine professional that he is, he conducted a thorough research and soon came across the Fouling Release Foil by HATAG maritime. He eventually had his own boat, plus the 55-foot catamaran of a friend, wrapped in the Fouling Release Foil below the waterline. “The boats have now been protected by the FRF Foil for about nine months on average, and all I can say is that it works remarkably well!” When Steve later visited Europe, he took the opportunity to visit HATAG maritime in Hamburg, Germany, as well as GTF Freese in Bremen, specializing in corrosion protection, to get to know the FRS Fouling Release System that is the result of a cooperation between the two companies. What he saw there impressed him and when Harald Tagsold of HATAG maritime asked Steve if he did not want would like to represent the company in his part of the world, he accepted: “Although I am quite busy with my other commitments this was a good opportunity. The foil and especially the FRS system, where the foil is applied on a specially formulated, epoxy-based primer, are the answer to all current demands for a non-toxic but efficient antifouling solution. It is a good thing to do, also for the world.” At the time of writing, the next projects in New Zealand were already coming up: A 15-metre power launch was wrapped in FRF foil in early February, another large catamaran will probably follow soon. “We have a lot of interest in the Fouling Release foil and system here”, Steve says. #foulingreleasesystem #foulingreleasefilm #antifouling #biocidefree #hatagfrf #hatagfrs #nz

HATAG in der Special Interest Presse – WAVE Magazin 54

TECHNIQUE Underwater protection for yachts INNOVATIVE AND ENVIRONMENTALLY FRIENDLY Bonding instead of painting: Similar to land-based vehicles, yachts are increasingly being "foiled" above the waterline instead of painted. For some time now, however, there has also been an application as protection against unwanted growth in the underwater area, as an alternative to conventional antifouling paints. As a consequence, these coatings, which are based on the fact that they gradually release toxins into the surrounding water during the course of their service life, will no longer be permitted on more and more bodies of water, either today or in the near future. Legislation to this effect has already been passed or is in preparation in many parts of the world. A non-toxic underwater protection system is a silicone-based film that has been developed in recent years primarily for the particularly challenging conditions in commercial shipping. The FRF Fouling Release Film from Hamburg-based HATAG maritime is non-toxic, its action based on a silicone-based flouropolymer film applied to the underwater hull. In combination with an epoxy primer specially developed for use with the film, this FRS system also provides highly effective protection against corrosion and osmosis. Various yachts on the Baltic Sea and in the Mediterranean Sea are protected with the film in the underwater area. The film remains effective for years, eliminating the need for annual painting with antifouling paints for at least five to seven years. In case of mechanical damage caused by grounding or similar, the film can be easily repaired, i.e. reapplied to the damaged areas. In any case, it is robust enough for normal operation of the yacht, including, for example, the annual craning out or in by means of a travel lift. Authorized applicator www.cfc.de/maritim #foulingreleasesystem #hatagmaritime #foulingreleasefilm #antifouling #biocidefree #hatagfrf #hatagfrs #freese #tefrocor150 #maritime #future

Let’s talk about HATAG’s COMMITMENT

DEVELOPING SUSTAINABLE SOLUTIONS We have always been convinced that true progress is the one respecting the world we live in, and that our eco-friendly solutions should benefit to the greatest number. Since innovation only takes on its full meaning if it is spread, and since the most extraordinary inventions are only of interest if they are shared, Hatag Maritime relies on its own technological advances and those of its partners to design, develop, and produce accessible, high-performance solutions meeting the major challenges of our time. THE GLOBAL GOALS In 2015, world leaders agreed to 17 Global Goals (officially known as the Sustainable Development Goals or SDGs). These goals have the power to create a better world by 2030, by ending poverty, fighting inequality and addressing the urgency of climate change. Guided by the goals, it is now up to all of us, governments, businesses, civil society and the general public to work together to build a better future for everyone. HATAG Maritime is committed especially to the following two global goals: GOAL 13 Climate change is a real and undeniable threat to our entire civilization. The effects are already visible and will be catastrophic unless we act now. Through education, innovation and adherence to our climate commitments, we can make the necessary changes to protect the planet. These changes also provide huge opportunities to modernize our infrastructure which will create new jobs and promote greater prosperity across the globe. GOAL 14 Healthy oceans and seas are essential to our existence. They cover 70 percent of our planet and we rely on them for food, energy and water. Yet, we have managed to do tremendous damage to these precious resources. We must protect them by eliminating pollution and overfishing and immediately start to responsibly manage and protect all marine life around the world. #foulingreleasesystem #hatagmaritime #foulingreleasefilm #antifouling #biocidefree #hatagfrf #hatagfrs

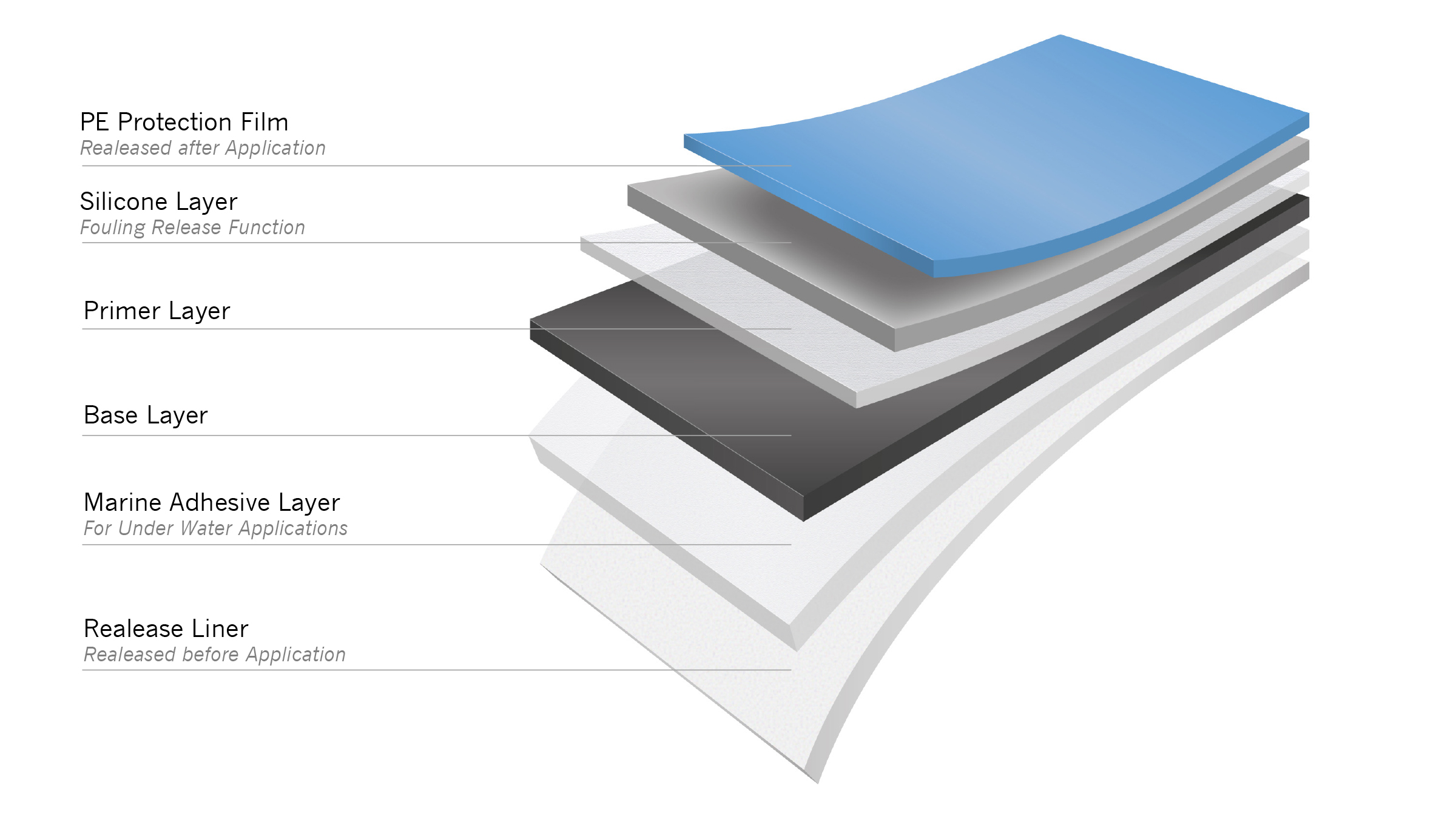

The FRS System

The FRS System. Two Partners, Two Products, One System. HATAG maritime has developed a joint project with the company GTF Freese in Bremen: The innovative antifouling system FRS-System. This is based on the HATAG Fouling Release Film FRF 630 and the specially developed adhesive primer TEFRO®cor 150 SW-LV from the coating experts at Freese. Through the combination of these two highly developed products, the system offers unbeatable advantages both in application and, of course, in its effect as efficient long-term protection against corrosion and unwanted fouling. Another valuable advantage for shipping is the fuel saving on a ship coated with the FRS system. This saves significant costs and, of course, C02 emissions. The coating with the FRS system is permanently robust and made for the tough conditions of commercial shipping. The specially developed primer is one hundred percent matched to the properties of the film. It is solvent-free, epoxy-based, can be applied in just one layer without additional primer and does not require a multi-layer paint structure. Application is therefore extremely simple and time-saving, without the risks of bubbles, cracks or shrinkage. The epoxy-based adhesive primer provides a highly effective barrier against moisture, as effective protection against corrosion or osmosis, depending on the material of the structure. GTF Freese has been in the surface coating business for 100 years and now, in combination with the HATAG FRF Fouling Release Film, offers the perfect protection system for all areas under water. For commercial vessels, cargo ships and ferries, navigation marks and other maritime structures as well as yachts. https://lnkd.in/eP2CsvpG #foulingreleasesystem #hatagmaritime #foulingreleasefilm #antifouling #biocidefree @hatagmaritime @hatagfrf @hatagfrs @freese #tefrocor150

Partnership

Hatag maritime enters into strategic partnership with CFC®CarFilmComponents® for professional application of FRS and FRF films. CFC®CarFilmComponents® is a medium-sized company that has been dedicated to film technology since 1998. The core competence of this company is in the field of film, and CFC operates an assembly network for film technology at over 120 locations in Germany alone. In most European countries, CFC and its distributors also carry out professional film installations in a wide variety of areas, such as automotive, building, maritime, leisure and advertising technology. This makes it the ideal partner for HATAG maritime to carry out reliable and high-quality applications of FRF films and the FRS system. And this, thanks to the strong network, at all locations in Germany and Europe. In addition, the company offers certified training for beginners and professionals with its own "CFC Academy". Adapted to current market demands, we pass on our many years of experience to our training participants in a way that is easy to understand and implement. At other locations, HATAG maritime also conducts its own training courses to train qualified and certified applicators. More information on CFC: www.cfc.de/maritim #foulingreleasesystem #hatagmaritime #foulingreleasefilm #antifouling #biocidefree @hatagmaritime @hatagfrf @hatagfrs

The Flying Film

We, the founders of HATAG maritime, have been working for many years on a solution for the ecologically and economically effective coating of ship hulls and other maritime structures, especially in the underwater area. Our innovative new foil will make toxic paints with all their problems obsolete from now on and for the future. But of course the idea of "film instead of paint" also works in other areas of application in global transport. We are very pleased, for example, that the airline "Swiss" is covering its entire fleet of Boeing 777-300s with the riblet film "AeroSHARK" developed jointly by Lufthansa Technik and BASF. This new surface coating, which is said to be based on a reproduction of shark skin, not only significantly reduces the frictional resistance of the aircraft. Just as with our own FRS system for shipping, the reduced frictional resistance in each case noticeably saves fuel, and thus emissions. In the case of Swiss' aircraft, according to a BASF press release, this is as much as 1.1 per cent fuel: "Converted to the operational profile of the Boeing 777-300ER at SWISS, this means an annual saving of more than 4,800 tonnes of paraffin and around 15,200 tonnes of carbon dioxide, as much as is usually produced on around 87 long-haul flights from Zurich to Mumbai," it says. "AeroSHARK" is a surface technology developed jointly by Lufthansa Technik and BASF that consists of ribs about 50 micrometers in size - the so-called riblets. It specifically imitates the properties of the particularly streamlined shark skin and thus optimises the aerodynamics at relevant points of the aircraft. As a result, less fuel is needed overall. Lufthansa Technik and BASF intend to consistently develop the new technology further with a view to additional aircraft types and even larger surfaces, so that in the future they will be able to support airlines around the world in achieving their emission goals. In initial model calculations, the sharkskin technology in its maximum expansion stage could even avoid CO2 emissions on the scale of up to three percent." So much for the press release. Of course, it is just as crucial for the aviation industry as it is for the shipping industry to significantly reduce their respective ecological footprints in the coming years. The fact that this can also be achieved with economic benefits through solutions like these is all the more pleasing. Already today, some ships are sailing with the HATAG FRS system film. Fuel-saving and without toxic antifouling paint. You can find all information about our FRS system on these pages or by contacting us directly. #foulingreleasesystem #hatagmaritime #foulingreleasefilm #antifouling #biocidefree @hatagmaritime @hatagfrf @hatagfrs @basf @aeroshark

THE FUTURE, NOW

All underwater fleet hulls and submerged surfaces should be smooth and free of “stowaways” in the form of biological matter. This will prevent species from being transported from one climate zone to another. Doing so significantly reduces underwater drag and increases efficiency of propulsion systems. That in turn reduces related operational costs and emissions. Hatag FRF Fouling Release Film is the solution to this challenge. The product provides a reliable and effective biocide-free fouling prevention film specifically designed for permanent application on all underwater maritime structures and equipment. The foil is robust, durable and provides reliable non-toxic protection against marine fouling. This efficiency is DNV certified. #hatagmaritime #hatagfrf #foulingreleasefilm #antifouing #hatagfrf630 #cleanocean #responsibility

OUR MISSION

The oceans are the main arteries of the global economy. They are simultaneously the arena for the climate crisis battle. Protecting our oceans and preserving the function of oceanic ecosystems is the basis of our efforts to leave a habitable planet for future generations. Without living oceans, there is no life on earth! Modern shipping operations has a serious responsibility to implement measures in all aspects of shipping operations which promote the protection the oceans. We at HATAG Maritime offer the solution via the manufacture, supply and application of biocide-free underwater coatings to achieve that protection. In addition to ensuring a non-toxic solution to the problem, it achieves significant emission and cost savings.#hatagmaritime #hatagfrf #foulingreleasefilm #antifouling #ourmission #biocidefree #nontoxicsolutions #costsaving

Review

Review: In October 2021, HATAG maritime presented its mission and innovative fouling release films in a B2B presentation at the Maritime Transport Efficiency Conference in Geneva, Switzerland #maritime #b2b #hatagmaritime #foulingreleasefilm #foulingreleasesystem #antifouling #